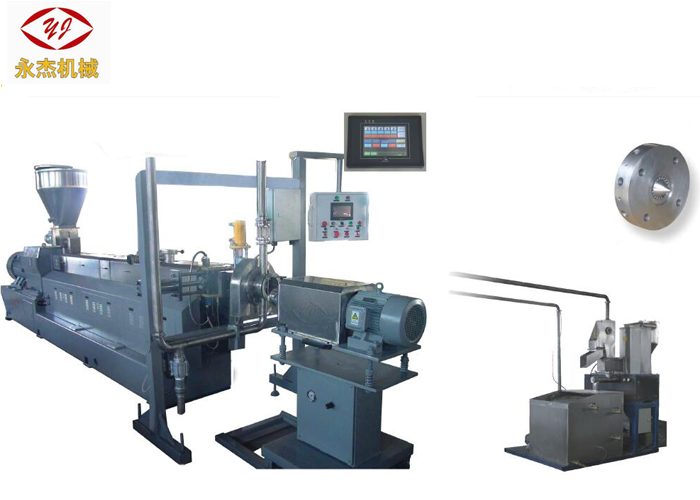

HDPE / LLDPE Extruder Mīkini, PLC Underwater Pelletizing Unit 132kw Motor

| Hoʻolālā Screw: | Mālua Screw Extruder | Noi: | LLDPE LDPE HDPE |

|---|---|---|---|

| ʻEnekinia o nā ʻāina ʻē: | Loaʻa no ka hoʻokomo ʻana a me ke kau ʻana | Barela anawaena: | 71.8mm |

| kaʻa kaʻa: | 132kw | Pūnaehana hoʻoheheʻe pahu: | 2.4kw |

| L/D: | 44 A i ʻole 48:1 | Mea hoʻoheheʻe wai: | 5.5kw |

LLDPE LDPE HDPE Underwater PLC Twin Screw Extruder Plastic Extrusion Machine

ʻO Nanjing Yongjie i lalo o ka wai plastic pellet machine ka mea kūikawā a me ka hana hou no ka hana ʻana

hgih-quality plastics pellets, nona ka viscosity haʻahaʻa a me ka elasticity kiʻekiʻe, a i ʻole ke ʻano kūikawā, e like me ka micro-particle.

Noi maʻamau:1. Polyolefine:LLDPE, LDPE, HDPE, PP, EPDM…2. Styrolpolymere:PS, ABS…3. ʻAila:PMMA…4. Polyacetale:POM…5. Polycarbonate:PC, PET, PBT, PE…

6. Polyamide:PA6,PA6.6,PA11,PA12…7. Thermoplastics Elastomer:TPE,TPV,TPR,TPEE…8.Hot hehee adhesives:TPU, EVA, PA, PP

Nā kikoʻī wikiwiki

Mana: 160kw

Mea wili:W6Mo5Cr4V2

ʻO ka pahu pahu:45# kila forged me ka 101 abrasion-resistant alloy 101 (Ni-Fe-Cr-W) i loko o ia laumā.

a me ka abrasion.ʻO ka paʻakikī HRC60-64.

L/D:44 a i ʻole 48:1

Output: 500-600kg / h e like me nā mea like ʻole, ka hoʻohālikelike a me ka ʻenehana o ka hana etc.

Nā hoʻololi: 0-600rpm;

Lakiō hoemi: i = 2.5:1

ʻO nā ʻāpana nui o ka mīkini

| ʻAʻole. | ʻIkepili | Unite | Ka nui | Mākaʻikaʻi |

| 1 | Pūnaehana hoʻoheheʻe māhoe māhoe | hoʻonoho | 1 | |

| 1.1 | Pūnaehana hānai | hoʻonoho | 1 | 1.5kw |

| 1.2 | SJ-75 Twin screw extruder | hoʻonoho | 1 | 132kw, 40:1 |

| 1.3 | Pūnaehana hoʻoheheʻe ʻana | hoʻonoho | 1 | 2.2kw |

| 1.4 | Pūnaehana holo kaʻa wai | hoʻonoho | 1 | 0.55kw |

| 1.5 | Mea hoʻololi pale ʻakomi | hoʻonoho | 1 | 1.5kw |

| 2 | Keena uila | hoʻonoho | 1 | |

| 3 | Underwater pelletizing auxiliary mīkini ʻōnaehana | hoʻonoho | 1 | |

| 3.1 | Pūnaehana pahu pahu pahu | hoʻonoho | 1 | 2.4KW |

| 3.2 | ʻOki poʻo | hoʻonoho | 1 | |

| 3.3 | Pūnaehana pahi ʻoki | hoʻonoho | 1 | 4KW |

| 3.4 | Pneumatic valve | hoʻonoho | 1 | |

| 3.5 | Mea hoʻoheheʻe wai | hoʻonoho | 1 | 5.5KW |

| 3.6 | Keena uila | hoʻonoho | 1 | |

| 3.7 | vibrator | hoʻonoho | 1 | 0.4KW |

| 3.8 | Hoʻokahi pae ʻōnaehana hoʻoili puhi | hoʻonoho | 1 | |

| 4 | Palapala | hoʻonoho | 1 |

Pāʻoihana Pāʻoihana

Ka manawa alakaʻi: 45 mau lā ma hope o ka waiho ʻana

Loaʻa nā ʻenekinia no ka hoʻokomo ʻana i nā ʻāina ʻē, ka hoʻouna ʻana etc

Uku manawa: 30% waiho ma o TT, 70% koena ma mua o ka hoʻouna ʻana ma hope o ka hoʻāʻo ʻana a me ka hoʻomaʻamaʻa ʻana i ka mīkini ma ka mea kūʻai aku o ka mea kūʻai aku, hiki ke kūkākūkā ʻia ka uku L / C

Nā inoa kaulana o ka honua o nā mea uila

1).He Kepani ka mita hoʻomalu welaRKCmika, ʻano naʻauao, kaila pālua;

2).ʻO ka inverter o extruderABB;

3).Hoʻohana ʻia nā mea hana haʻahaʻa haʻahaʻa a me ke pihiSCHNEIDERhuahana;

4).Hoʻohana ʻia ka mea hoʻopili ACSIEMENShuahana;

5).ʻO ke kaʻa nuiSISMENS MA KA HOPE;

6).Hoʻohana ka ea hoʻololiCHINThuahana.ʻO nā relay mokuʻāina paʻa mai ʻAmelika Hui Pū ʻIa;

7).ʻO ka valve electromagnetic: hoʻohana iā DenmarkDANFOSShuahana.

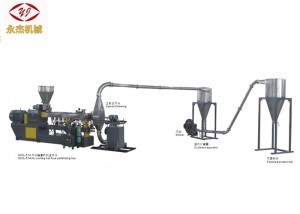

Kiʻi o TPU TPE TPR EVA Underwater Plastic Granules Pelletizing Machine

ʻIke ʻenehana nui o nā ʻano hoʻohālike like ʻole o ka mīkini pelletizing twin screw extruder

| ʻAno hoʻohālike | moʻo | Ka Anawaena Barela (mm) | Ka Anawaena Uila (mm) | Screw L/D | ka māmā holo n(r/min) | Ka mana kaʻa nui (Kw) | T(Nm) | Ka helu ʻana o ka Torque (T/A3) | Ka mana hana maʻamau (kg/h) |

| SJSL-36 | A/B/C/D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A/B/C/D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A/B/C/D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A/B/C/D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A/B/C/D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A/B/C/D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |

Pōkole Hui

Nanjing Yongjie Qixin Machinery Equipment Co., LtdHoʻokumu ʻia i ka makahiki 2001, e uhi ana i kahi ʻāpana o 20,000 square meters ma ko mākou ʻāina ponoʻī, me ka puka ʻana o ka mīkini 20sets i kēlā me kēia mahina.Hoʻopaʻa ʻia kā mākou hale hana iā CE, ISO9001: 2008. Hoʻokumu ka ʻoihana i ka noiʻi, hoʻomohala a me ka hana ʻana o "ka pae kiʻekiʻe, pololei, ʻoi loa ka maʻalahi o ka moʻo huahana like pū me ka rotating "cordwood" twin screw extruder, single screw extruder, ʻelua pae extruders a nā mīkini pelletizing plastic.Ua hoʻolako mākou i nā mea kūʻai aku i nā huahana papa mua me ka "torque ikaika, hana kiʻekiʻe, mālama i ka ikehu a me nā huahana palekana kaiapuni.Ua hoʻokō maikaʻi ʻia ka ʻōnaehana hoʻolālā kūikawā no ka "hoʻokahi papa hana" ma nā ʻano huahana he nui, a hoʻohana nui ʻia i ka pā alumini composite, XPS foaming plate, WP plate, PP, PE sheet industry, etc.

HOOMAIKAI KA ANOAI MA KA MUA , a ua palapala ʻia kā mākou hale hana ISO 9001:2008 a CE.