Kab rov tav PVC Pelletizing Tshuab Siab Torque Kub Txiav Twin Ntsia Hlau Extruder

| Ntsia Hlau Tsim: | Twin Ntsia Hlau Extruder | Daim ntawv thov: | Pvc pellets |

|---|---|---|---|

| Gearbox: | 800 rpm Siab Torque | Khoom siv: | 38CrMoAL Nit-ridged hlau |

| Ntsia Hlau Diameter: | 6 2,4mm | Lub cev muaj zog: | 132 kwv |

| Overseas Engineering: | Muaj Rau Kev Txhim Kho Thiab Kev cob qhia | Cov zis: | 400-550 Kg / h |

Nanjing High Torque SJSL65D Kub Txiav Twin Ntsia Hlau Extruder PVC Pelletizing Tshuab

Cua Txias Tuag Lub ntsej muag PVC Pelletizing Tshuab Daim Ntawv Thov

Txhim kho kev hloov kho:PE, EVA thiab lwm yam + Caco3, Talc, Tio2, PVC, PP, Carbon dub

Degradable Master batch:PE, PS thiab lwm yam + starch, additive thiab lwm yam

Anti-flake master batch:PE, EVA thiab lwm yam + Sb2o3, Mg(OH)2, AI2(OH)3lwm.

Cov ntsiab lus ceev

Lub zog: 132kw

Screw txoj kab uas hla: 62.4mm

Loj: 63mm

Gearbox: 800 rpm, txo qhov piv: 1.9: 1

Screw & chim khoom:38CrMoAl

Cov zis: 400-550kg / h

Txoj kev txiav: cua txias tuag lub ntsej muag rau pvc pellets

Warranty: ib xyoos

Lub sij hawm xa tuaj: 45 hnub tom qab tso nyiaj

Thaj chaw cua sov: 9 thaj chaw

Inverter hom: ABB

Iav lub thawv: siab torque, tawm tswv yim 1480rpm, tso zis 600rpm, txo qhov piv: 2.5: 1

Loj: 240 * 9 = 2160mm

Scope ntawm kev muab khoom

| Tsis muaj. | Cov ntsiab lus | Chav tsev | Ntau | Cov cim |

| 3 | Twin ntsia hlau extrusion system | teeb | 1 | |

| 3.1 | Pub noj system | teeb | 1 | 1.5 kwv |

| 3.2 | SJ-65 Twin ntsia hlau extruder | teeb | 1 | 132 kwm, 36:1 |

| 3.3 | Lub tshuab nqus tsev vacuum | teeb | 1 | 2.2 kwm |

| 3.4 | Dej cycling system | teeb | 1 | 0.55 kwm |

| 3.5 | Tsis siv neeg screen changer | teeb | 1 | 1.5 kwv |

| 4 | Hluav taws xob txee | teeb | 1 | PID |

| 5 | Cua txias auxiliary system | teeb | 1 | |

| 5.1 | Tuag taub hau | teeb | 1 | |

| 5.2 | Lub ntsej muag cutter | teeb | 1 | 1.5 kwv |

| 5.3 | ib-theem conveying system | teeb | 1 | 4 kwv |

| 5.4 | Vibrating sieve | teeb | 1 | 0.37 kwm |

| 5.5 | Cov khoom siv silo | teeb | 1 | |

| 6 | Cov ntaub ntawv | teeb | 1 |

Dawb spare qhov chaw:

| Tsis muaj. | Cov ntsiab lus | Chav tsev | Ntau | Cov cim |

| 1 | Ntsia hlau ntsiab | teeb | ~ 300 hli | |

| 2 | Output thiab input ncej roj foob | ib daim | 3 | |

| 3 | Venting room foob nplhaib | ib daim | 1 | |

| 4 | Asbestos hnab looj tes | khub | 2 | |

| 5 | Allen Key (zeeg) | teeb | 1 | 5 qab |

| 6 | Allen Ntsiab (nrog) | teeb | 1 | 3 qab |

| 7 | Hla, tiaj tus ntsia hlau tsav | ib daim | 1 cwb | 2 qab |

| 8 | Ntsia hlau hoisting nplhaib | ib daim | 2 | |

| 9 | Hniav | ib daim | 30 |

Kev pabcuam ua ntej muag

♦1.Kev nug thiab kev pab tswv yim.

♦ 2.Xaiv kev lag luam thiab tsim nyog extruder thiab lwm yam tshuab rau cov neeg siv khoom.

♦ 3.Muab cov ntsiab lus technical ntawm lub tshuab.

♦4.Muab cov txheej txheem kev sim ua haujlwm rau cov neeg siv khoom.

♦5.Factory ncig saib & kev pab ntawm tsab ntawv caw thaum xav tau.

Kev muag khoom

♦1.Pom zoo engineering tej yam kev mob uas yuav tsum tau rau installation.

♦ 2.Kev sib txuas lus raws sijhawm ntawm kev tsim khoom ntawm cov tshuab.

Kev pab cuam tom qab muag

♦1.Engineers muaj rau kev pabcuam machinery txawv teb chaws hauv kev teeb tsa, commissioning thiab kev cob qhia.

♦ 2.Ua kom nthuav dav cov neeg siv khoom cov ntaub ntawv xaj.

♦ 3.Muab kev pab tu mus sij hawm ntev thiab cov khoom seem.

♦4.Muab kev txhawb nqa rau cov neeg siv khoom tsim khoom tshiab.

♦5.Muab kev saib xyuas dawb rau ib xyoos

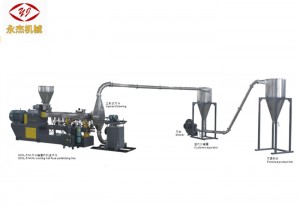

Duab ntawmNanjing SJSL65B Tuag ntsej muag PVC Pelletizing Tshuab PVC ABS Twin Ntsia Hlau Tshuab

Cov ntaub ntawv tseem ceeb ntawm ntau yam qauv ntawm ntxaib ntsia hlau extruder pelleitizing tshuab

| Hom qauv | Series | Lub taub hau (mm) | Ntsia Hlau Diameter (mm) | Ntsia Hlau L / D | ntsia hlau ceev n(r/min) | Main lub cev muaj zog (Kw) | Ntsia Hlau Torque T (Nm) | Kev ntsuas lub zog (T / A3) | Yam khoom muaj peev xwm (kg / h) |

| SJSL 20 | A/B | 22 | 21.7 ib | 32-44 : kuv | 500/600 | 4/5.5kw | 30/30 ib | ||

| TSW-36 | A/B/C/D | 36 | 35.6 ib | 32-48 : kuv | 400/600 | 11/15/18.5/22 | 125-225 : kuv | 4.6-8.3 | 30-120 Nws |

| NWS-51 | A/B/C/D | 51 | 50.5 ib | 32-52 : kuv | 500/600 | 45/55/75/90 ib | 405-680 : kuv | 5.1-8.5 | 120-400 Nws |

| TSW-65 | A/B/C/D | 63 | 62.4 ib | 32-64 : kuv | 500/600 | 75/90/110/132 | 680-1200 Nws | 4.8-8.5 Nws | 180-750 Nws |

| NWS-75 | A/B/C/D | 72 | 71 | 32-64 : kuv | 500/600 | 110/132/160/250 | 995-1890 ib | 4.6-8.7 Nws | 300-1200 Nws |

| NWS-95 | A/B/C/D | 94 | 93 | 32-64 : kuv | 500/600 | 250/315/450/550 | 2260-4510 Ib | 4.7-8.7 Nws | 700-2500 Nws |

| TSW-135 | A/B/C/D | 135 | 133 | 32-48 : kuv | 400/500 | 550/750/900/1200 | 6200-10800 Nws | 4.4-7.7 | 1550-6500 Nws |

Lub tuam txhab luv

Nanjing Yongjie Qixin Machinery Equipment Co., LtdFounded hauv 2001, npog thaj tsam ntawm 20,000 square metres ntawm peb tus kheej thaj av, nrog cov khoom siv txhua hli ntawm tshuab 20sets.Peb lub Hoobkas muaj ntawv pov thawj rau CE, ISO9001: 2008.Lub tuam txhab tsom rau kev tshawb fawb, kev tsim kho thiab tsim khoom ntawm "theem siab, raug, cov khoom lag luam zoo heev uas sib luag co-rotating "cordwood" ntxaib ntsia hlau extruder, ib qho ntsia hlau extruder, ob theem extruders thiab tsis siv neeg yas pelletizing tshuab.Peb tau muab cov neeg siv khoom ua ntej cov khoom lag luam nrog "muaj zog torque, ntau lawm, kev txuag hluav taws xob thiab cov khoom tiv thaiv ib puag ncig.Cov qauv tsim tshwj xeeb ntsia hlau tau pom zoo rau "ib kauj ruam shaping" ntawm ntau yam khoom, thiab yog siv dav hauv aluminium composite phaj, XPS foaming phaj, WP phaj, PP, PE daim ntawv kev lag luam, thiab lwm yam.

Yuav ua li cas xaiv tshuab rau yas pellet?

1. Cia li qhia peb koj cov qauv ntxhib?

2. Koj xav tau cov zis ib teev ntawm mahcine