0.26kw Dryer Filler Masterbatch Machine Low Voltage Power Supply Standard SJSL36

| Nhazi screw: | Ejima ịghasa Extruder | Ngwa: | PP PE na Caco3, Talc Etc Filler Masterbatch |

|---|---|---|---|

| Akwụkwọ ikike: | Otu afọ | Drier | 0,26kw |

| L/D: | 44:1 | Ihe mkpuchi & Barrel: | W6Mo5Cr4V2 |

| moto: | 18.5kw | Ike: | 30-150kg / h |

SJSL36 High Filler Masterbatch Machine Water Ring Twin Screw Pelletizing Machine

Ngwa pelletizer mgbanaka mmiri:

1. PE, Eva wdg + Caco3, okwu, Tio92, ndochi mgbanwe na carbon ojii wdg.

2. LDPE, HDPE, LLDPE, MDPE, drivepipe, ihe mkpuchi ihe, crosslinking, cable cover, thermal contraction pipe material etc.

3. PPR ọkpọkọ ogige, PE crosslinking tube ihe, TPR, TPU thermoplastic elastomer, Eva na ọkụ gbazee nrapado wdg.

4. PE, ABS, PS, EVA masterbatch wdg.

5. ABS, Eva flaming retarding masterbatch wdg.

6. PE, PP, PS ndochi na biodegradable masterbatch, wdg.

Nkọwa ngwa ngwa nke pelletizer mmiri mgbanaka sjsl36

Nọmba nlereanya: SJSL36B

dayameta nke ịghasa: 35.6mm

Ihe ịghasa: W6Mo5Cr4V2

Dayameta Barrel: 36mm

Ihe eji eme gbọmgbọm: W6Mo5Cr4V2

Ike moto: 18.5kw

Ụdị moto: SIEMENS

L/D:44:1

Mpụta: 30-100kg / h

chọrọ teknụzụ:

Data dị ike:Obere ọkụ ọkụ ọkụ ọkọlọtọ (DIN/IEC38): 380 v -5 + 10%, 50Hz-/+ 2% frasi/N/PE 50Hz.

ọkọlọtọ voltaji njikwa (gbanwere):220V AC ( contactor, mita, valvụ electromagnetic).Okpomọkụ: 10-40 ℃.

iru mmiri: max.80%, enweghị condensation.

Mgbakọta watj:~50kw.

Mmiri chọrọ:Mmiri na-ekesa: Mmiri na-eme ka mmiri dị jụụ na gbọmgbọm ga-abụ mmiri dị nro (mmiri distilled).

Isi mmalite mmiri:1. Ịmepụta ọdọ mmiri (4-6 ㎥) n'èzí theworkshop, na-eji mmiri mgbapụta na-eme ka recycling mmiri.

2. Iji mgbata mmiri ozugbo, mana ọ na-efunahụ ya.

Arọ:Extruder:~2T Sistemụ inyeaka:~1T

Ncheta:Biko gụọ nkọwapụta mmepụta tupu imeghe akụrụngwa.

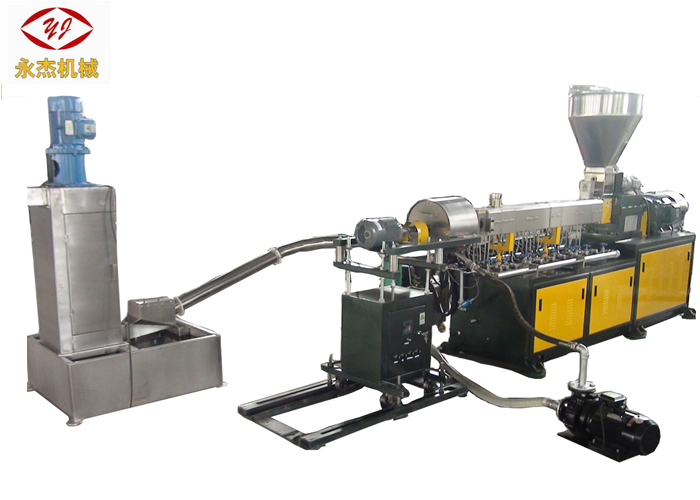

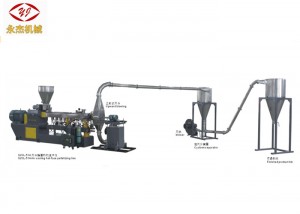

Foto nke SJSL36 Water Ring Filler Masterbatch Machine

Akụkụ mapụtara n'efu:

| Mba. | ọdịnaya | Nkeji | Ọnụọgụ | Akara |

| 1 | Ihe ịghasa | setịpụrụ | ~ 100mm | |

| 2 | Mmepụta na ntinye akara mmanụ aro | ibe | 3 | |

| 3 | mgbanaka akara ventilashị | ibe | 1 | |

| 4 | Asbestos uwe aka | ụzọ abụọ | 2 | |

| 5 | igodo Allen (n'ime) | setịpụrụ | 1 | 5 iberibe |

| 6 | igodo Allen (mpụta) | setịpụrụ | 1 | 3 iberibe |

| 7 | Flat, Cross Screw ọkwọ ụgbọ ala | ibe | 1 nke ọ bụla | 2 iberibe |

| 8 | Ogwe ọla kọpa ∮32*200 | ibe | 1 | |

| 9 | Mgbanaka mkpuchi mkpuchi | ibe | 2 | |

| 10 | Cutter | ibe | 30 |

Isi nkọwa nka nka nke ụdị mgbanaka mmiri dị iche iche

| Ụdị ụdị | Usoro | Dayameta Barrel (mm) | Dayameta ịghasa (mm) | Mkpọsa L/D | screw speed n(r/min) | Ike moto (Kw) | Screw torque T(Nm) | Ọnụọgụ torque (T/A3) | Ike mmepụta ihe (kg/h) |

| SJSL-36 | A/B/C/D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A/B/C/D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A/B/C/D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A/B/C/D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A/B/C/D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A/B/C/D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |