0.25kw Feeder Co Rotating Twin Screw Extruder, Mesin Extruder Skala Laboratorium

| Desain Screw: | Co-puteran Parallel Twin Screw Extruder | Aplikasi: | Formula Polimer Testing |

|---|---|---|---|

| Sistem pendinginan: | Soft Non-inoic Distilled Water | Bahan sekrup & laras: | 38 Baja Nitridge CrMoAL |

| Diameter barel: | 22 mm | Panjang Barel: | 120mm * 7 bagean = 840mm |

| Kapasitas: | 2-15kg / jam | Feeder: | 0,25 kw |

2-15kg/jam 20mm Mini Extruder Laboratorium Plastik Mesin Pelet Lab Twin Screw Extruder

Karakteristik extruder meneng kembar

Ing noto meneng diadopsi "dolanan bata" asas, kang Déwan miturut mesin beda L / D, cara dipakani beda, tong minyak beda lan kombinasi meneng, beda layar ganti lan nglereni cara, mode kontrol electrical beda, etc. materi lan proses teknologi.Menehi wawasan kanggo unive plastikDhasar kekarepan panggolékan lan kagunaan kang umum saka approprikabisan.

Yongjie laboratorium mini extruder SJSL20 digunakake digunakake ing antarane para pelanggan universitas, pusat riset, lan departemen R&D pabrik kanggo tes rumus, senyawa dll.

Rincian cepet

Daya: 5,5 kw

Diameter sekrup: 21,7 mm

Bahan sekrup: 38CrMoAL

Diameter barel: 22mm

Bahan laras: 38CrMoAL

Output: watara 2-15kg / h

Cara nglereni: untaian banyu, untaian pendingin udara uga kasedhiya

Garansi: setaun

Lead time: 45 dina sawise simpenan

Daya panas: 16 kw

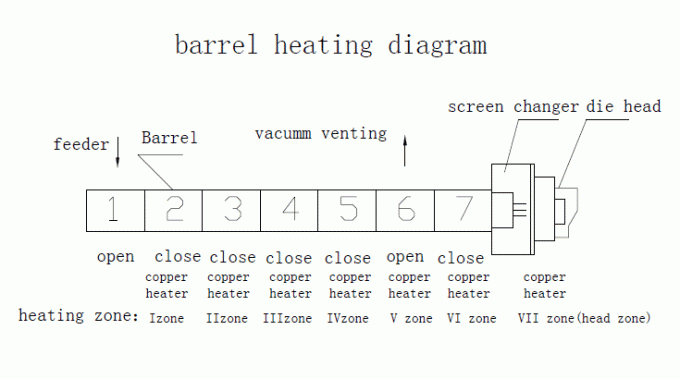

Zona pemanasan: 7 zona

Barel dawa: 120 * 7 = 840mm

Tipe kontrol: PID

Foto sakaLaboratorium Mini Extruder PVC Pelletizing Machine Pvc Kabel Extruder

Data teknis utama macem-macem model mesin pelleitizing extruder kembar

| Tipe model | Seri | Diameter barel (mm) | Diameter sekrup (mm) | Screw L/D | kacepetan meneng n(r/min) | Daya motor utama (Kw) | Torsi sekrup T (Nm) | Rating torsi (T/A3) | Kapasitas produksi khas (kg/jam) |

| SJSL20 | A/B | 22 | 21.7 | 32-44 | 500/600 | 4/5,5 kw | 30/30 | ||

| SJSL-36 | A B C D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A B C D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A B C D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A B C D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A B C D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A B C D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |

Ringkesan Perusahaan

Nanjing Yongjie Qixin Machinery Equipment Co., LtdFounded in 2001, isine area 20.000 kothak meter ing tanah kita dhewe, karo output saben wulan saka mesin 20sets.Pabrik kita wis sertifikat CE, ISO9001: 2008. Perusahaan konsentrasi ing riset, pangembangan lan produksi "tingkat dhuwur, akurat, produk seri Highly canggih paralel co-puteran" cordwood "extruder meneng kembar, extruder meneng siji, extruders rong tahap lan mesin pelletizing plastik otomatis.Kita wis nyedhiyakake pelanggan produk kelas siji kanthi "torsi kuwat, produksi dhuwur, konservasi energi lan produk perlindungan lingkungan.Struktur meneng dirancang khusus wis temen maujud kasil kanggo "siji langkah mbentuk" ing macem-macem produk, lan digunakake digunakake ing piring aluminium komposit, XPS piring foaming, piring WP, PP, industri sheet PE, etc.

Cara milih mesin kanggo pelet plastik?

1. Cukup marang kita rumus kasar?

2. output samesthine saben jam saka mahcine