Water Ring Hot Cutting Polymer Extrusion Machine 45#Forged Steel Barrel Material

| Desain Screw: | Twin Screw Extruder | Aplikasi: | LDPE, LLDPE, HDPE, PP PE, lsp |

|---|---|---|---|

| Diameter barel: | 63 mm | Diameter sekrup: | 62,4 mm |

| Motor: | 75kw | Kapasitas: | 200 kg/jam |

| L/D: | 48:1 | Bahan Barel: | 45#Tempa Baja |

LLDPE LDPE PE PP Water Ring Hot Cutting Polymer Extrustion Machine Mesin Pelletizing Plastik

Aplikasi Water Ring Pelletizer:

1. PE, Eva etc + Caco3, Dhiskusi, Tio92, ngisi modifikasi lan karbon ireng etc.

2. LDPE, HDPE, LLDPE, MDPE, drivepipe, bahan isolasi, bahan crosslinking, bahan lapisan kabel, bahan pipa kontraksi termal lsp.

3. Senyawa pipa PPR, bahan tabung crosslinking PE, TPR, elastomer termoplastik TPU, EVA lan adesif leleh panas dll.

4. PE, ABS, PS, EVA masterbatch etc.

5. ABS, EVA murub retarding masterbatch etc.

6. PE, PP, PS Isi lan masterbatch biodegradable, etc.

Rincian cepet

Daya: 75 kw

Bahan sekrup: W6Mo5Cr4V2

Bahan laras:45#baja tempa kanthi paduan tahan abrasi 101 (Ni-Fe-Cr-W) ing jero sing mulus

lan tahan abrasi.Kekerasan yaiku HRC60-64.

L/D:44:1

Output: 500-600kg / h miturut materi beda, rumus lan teknologi proses etc.

Revolusi: 0-500rpm;

Rasio reduksi: i = 3:1

Gear transmisi: Struktur tri-aksial paralel minangka kombinasi reduksi lan matriks.Gear digawe saka alloy kualitas dhuwur.Wis diolah kanthi proses panas sementasi, kelas presisi bisa tekan 6th.Iku njamin lumahing waos kacepetan dhuwur, overloading,swara kuranglantorsi dhuwur.

bantalan drive: Merk axletree:NSK.

Lubrication: Bantalan gear ing kothak gear bakal dadi lenga sing dicemplungake.Ana lubrication hydraulic ing engagement gear lan bantalan gear.

adhem: Cooling lubricated adopts cangkang lan tabung adhem lan sirkulasi cara cooling banyu.

Dhiameter:¢62,4 mm

L/D:44:1

Arah rotasi: Co-rotating

Meneng & unsur: W6Mo5Cr4V2(6542#) baja alat kacepetan dhuwur sing wis dianggep dening proses hardening vakum karo atose lumahing punikaHRC58-62.Molding liwat mesin grinding darmabakti.Kebersihan luwih apik tinimbang produk saka proses tradisional.

poros inti:Baja paduan kualitas dhuwur40CrNiMosing karo tenacity dhuwur lan kekiatan.Wis diobati kanthi proses hardening lan tempering.

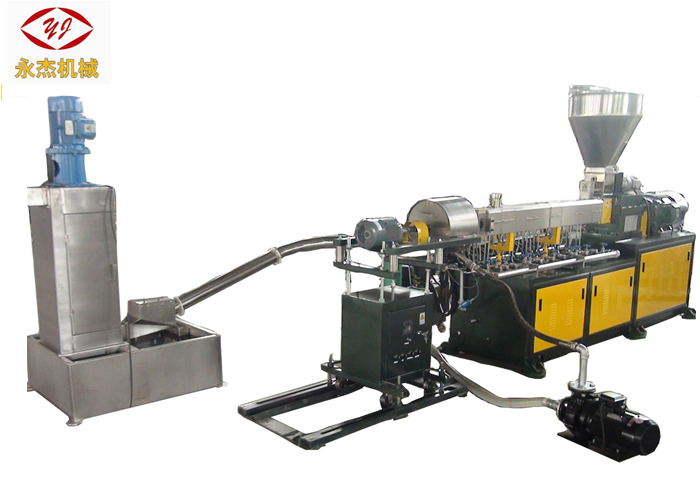

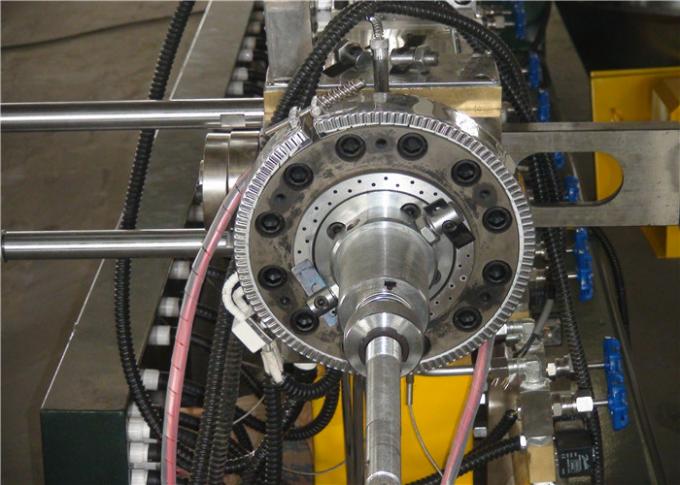

Foto LLDPE, LDPE, HDPE, TPR Twin Screw Water Ring Pelletizer Mesin Pelet Plastik

Data teknis utama macem-macem model mesin pelletizing extruder kembar

| Tipe model | Seri | Diameter barel (mm) | Diameter sekrup (mm) | Screw L/D | kacepetan meneng n(r/min) | Daya motor utama (Kw) | Torsi sekrup T (Nm) | Rating torsi (T/A3) | Kapasitas produksi khas (kg/jam) |

| SJSL-36 | A B C D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A B C D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A B C D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A B C D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A B C D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A B C D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |

Ringkesan Perusahaan

Nanjing Yongjie Qixin Machinery Equipment Co., Ltd Founded in 2001, isine area 20.000 kothak meter ing tanah kita dhewe, karo output saben wulan saka mesin 20sets.Pabrik kita wis sertifikat CE, ISO9001: 2008. Perusahaan konsentrasi ing riset, pangembangan lan produksi "tingkat dhuwur, akurat, produk seri Highly canggih paralel co-puteran" cordwood "extruder meneng kembar, extruder meneng siji, extruders rong tahap lan mesin pelletizing plastik otomatis.Kita wis nyedhiyakake pelanggan produk kelas siji kanthi "torsi kuwat, produksi dhuwur, konservasi energi lan produk perlindungan lingkungan.Struktur meneng dirancang khusus wis temen maujud kasil kanggo "siji langkah mbentuk" ing macem-macem produk, lan digunakake digunakake ing piring aluminium komposit, XPS piring foaming, piring WP, PP, industri sheet PE, etc.