Heavy Duty Plastic Recycling Pellet Machine W6Mo5Cr4V2 Screw & Barel Material

| Screw Design: | Twin Screw Extruder | Application: | PP PE NeCaco3, Talc Etc Filler Masterbatch |

|---|---|---|---|

| Warranty: | Gore rimwechete | Nguva Yekutungamira: | Mazuva 45 Pashure Deposit |

| Bharel Diameter: | 50.5mm | Screw & Barrel Material: | W6Mo5Cr4V2 |

| Motokari: | 45kw | Kugona | 100-250kg/h |

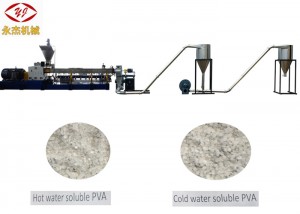

Black Masterbatch Extruder Mvura Mhete Pelletizer Twin Screw Extruder

Mvura Mhete Pelletizer Application:

1. PE, Eva etc + Caco3, kutaura, Tio92, kuzadza kugadziriswa uye carbon black etc.

2. LDPE, HDPE, LLDPE, MDPE, drivepipe, insulation material, crosslinking material, cable coating material, thermal contraction pipe material etc.

3. PPR pipe compounds, PE crosslinking tube material, TPR, TPU thermoplastic elastomer, EVA uye inopisa yakanyunguduka yakanamatira nezvimwewo.

4. PE, ABS, PS, EVA masterbatch nezvimwe.

5. ABS, EVA flaming retarding masterbatch etc.

6. PE, PP, PS kuzadza uye biodegradable masterbatch, nezvimwe.

Tsanangudzo dzinokurumidza dze sjsl36 mvura mhete pelletizer

Screw dhayamita: 50.5mm

Sirasi zvinhu:W6Mo5Cr4V2

Barel dhayamita: 51mm

Bhareri zvinhu:W6Mo5Cr4V2

Motokari simba: 45kw

Motokari mhando:SIEMENS

L/D:44:1 kana 48:1 zvichingodaro

Kubuda: 100-250kg/h

Mamiriro ebasa(yakapihwa nemutengi)

| Warehouse/Workshop | Dimension (M*M*M): 15 (Kureba)×3 (kufara) ×2.5 (Kureba)Crane: Machine positioning |

| Tembiricha | ≤40℃ |

| Simba rekupa & Kuisa simba | 3-chikamu,380V, 50Hz |

| Waya/tambo | Waya / tambo kubva kumagetsi ekudzora kabati yeiyi mutsara wekugadzira;Ese tambo dzemagetsi kubva ku control cabinet kusvika kumushini wega wega. |

| Kutonhodza Mvura hose/pombi | Kupihwa kwemvura kumichina nemadziva.Kugadzira dziva (4-6m3) kunze kwewekishopu, uchishandisa pombi yemvura kugadzira patsva mvura. |

| Kurema | Extruder: ~2.5T, sub-muchina: ~1T |

Zvikamu zvikuru uye michina parameters

| Aihwa. | Zviri mukati | Unit | Quantity | Marks |

| 1 | 100L high speed mixer | set | 1 | |

| 2 | Twin screw extrusion system | set | 1 | |

| 2.1 | Kudyisa system | set | 1 | 0.75kw |

| 2.2 | SJ-51 Twin screw extruder | set | 1 | 45kw, 44:1 |

| 2.3 | Vacuum venting system | set | 1 | 1.5kw |

| 2.4 | Mvura yebhasikoro system | set | 1 | 0.55kw |

| 2.5 | Otomatiki skrini inoshandura | set | 1 | 1.5kw |

| 3 | Magetsi kabati | set | 1 | |

| 4 | Mvura-mhete yekubatsira system | set | 1 | |

| 4.1 | Mvura-mhete kufa musoro | set | 1 | |

| 4.2 | Kucheka kumeso negwara njanji & chivharo | set | 1 | 1.5KW |

| 4.3 | Centrifugal dehydrator | set | 1 | 4KW |

| 4.4 | Vibrating sieve | set | 1 | 0.4KW |

| 4.5 | Bhini rekuchengetedza | set | 1 | |

| 5 | Zvinyorwa | set | 1 |

Huru Yehunyanzvi Ruzivo rweMvura Yakasiyana Mhete Pelletizer Models

| Muenzaniso mhando | Series | Dhiyamita yedhiramu (mm) | Screw Diameter (mm) | Screw L/D | screw speed n(r/min) | Main mota simba (Kw) | Sirivha torque T(Nm) | Torque mwero (T/A3) | Yakajairika kugadzira kugona (kg/h) |

| SJSL-36 | A/B/C/D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A/B/C/D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A/B/C/D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A/B/C/D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A/B/C/D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A/B/C/D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |