Hot New Products Filler Masterbatch Extruder Machine - Automatic Feeding Plastic Masterbatch Extruder PP Hdpe LDPE LLDPE Extrusion Machine – Yongjie

Hot New Products Filler Masterbatch Extruder Machine - Automatic Feeding Plastic Masterbatch Extruder PP Hdpe LDPE LLDPE Extrusion Machine – Yongjie Detail:

| Feeding: | Automatic Loss In Weight Feeding System | Application: | Plastic Pellets |

|---|---|---|---|

| Overseas Engineers: | Available For Installation And Comissioning | Screw Diameter: | 71mm |

| Motor: | 160kw | Capacity: | 500-6800kg/h |

| L/D: | 48:1 | Material Of Barrel: | 45#forged Steel |

Quick details

Feeding: loss in weight, automatic feeding.

Power:160kw

Screw material:W6Mo5Cr4V2

Barrel material: 45#forged steel with the abrasion-resistant alloy 101 (Ni-Fe-Cr-W) inside that smooth

and abrasion resistant. The hardness is HRC60-64.

L/D:48:1

Output:500-800kg/h according to different material, formula and technology of process etc.

Revolutions: 0-600rpm;

Reduction ratio: i = 2.5:1

Loss in weight feeding details

1) equipped with a feeder part installed on the weighing platform, with high-precision weighing sensor made by United States Toledo,

2) Weighing plastform is the square scale with material ss304;

3) all parts contacted with the raw material made of SS304, and easily-disasseable feeding part for fast change and easy clean. 4) no dead ball hopper, equipped with horizontal mixing;

5) Motor power: 1.5KW, speed ratio: 11: 1, with inverter speed control;

6) Microchip controller to ensure high accurate feeding, feeding accuracy can reach ± 0.5%. Standard power: 380V, 3-phase, 50 Hz;

7) with the hopper to ensure that the material into the barrel according to seted proportioning;

8) equipped with high and low level meter.

Business Clause

Lead time:45 days after deposit

Engineers available for overseas installation, commissioning etc

Payment term:30% deposit via TT, 70% balance before shipment after testing and qualifying machine at seller’s manufacturer, L/C payment are negotiable

Photo of automatic feeding system

Photo of SJSL75D Filler Masterbatch Machine

Main technical data of various model of twin screw extruder pelletizing machine

| Model type | Series | Barrel Diameter (mm) | Screw Diameter (mm) | Screw L/D | screw speed n(r/min) | Main motor power(Kw) | Screw torque T(N.m) | Torque rating (T/A3) | Typical production capacity (kg/h) |

| SJSL-36 | A/B/C/D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A/B/C/D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A/B/C/D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A/B/C/D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A/B/C/D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A/B/C/D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |

Company Brief

Nanjing Yongjie Qixin Machinery Equipment Co.,Ltd Founded in 2001, covers an area of 20,000 square meters on our own land, with monthly output of machine 20sets. Our factory is certificated to CE, ISO9001:2008.

The company concentrates on research, development and production of “high level, accurate, highly sophisticated series product parallel co-rotating “cordwood” twin screw extruder, single screw extruder, two stage extruders and automatic plastic pelletizing machines. We have provided customers first-class products with “strong torque, high production, energy conservation and environmental protection products. The special designed screw structure has realized successfully for “one step shaping” on many kinds of products, and is widely used in aluminum composite plate, XPS foaming plate, WP plate, PP, PE sheet industry, etc.

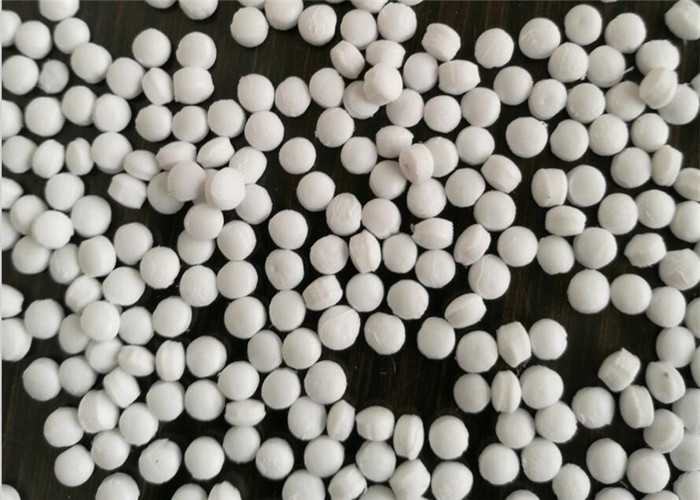

Product detail pictures:

Related Product Guide:

Cooperation

That has a positive and progressive attitude to customer's interest, our organization consistently improves our products quality to satisfy the demands of shoppers and further focuses on safety, reliability, environmental specifications, and innovation of Hot New Products Filler Masterbatch Extruder Machine - Automatic Feeding Plastic Masterbatch Extruder PP Hdpe LDPE LLDPE Extrusion Machine – Yongjie , The product will supply to all over the world, such as: Guatemala, Cape Town, Nepal, We expect to provide products and services to more users in global aftermarket markets; we launched our global branding strategy by providing our excellent products all over the world by virtue of our well reputed partners letting global users keep pace with technology innovation and achievements with us.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!