OEM Factory for Plastics Water Ring Pelletizer - 90kw Motor HDPE Granulator Pellet Manufacturing Equipment With Water Cycling System – Yongjie

OEM Factory for Plastics Water Ring Pelletizer - 90kw Motor HDPE Granulator Pellet Manufacturing Equipment With Water Cycling System – Yongjie Detail:

| Screw Design: | Twin Screw Extruder | Application: | PP PE With Caco3, Talc Etc Filler Masterbatch |

|---|---|---|---|

| Warranty: | One Year | Lead Time: | 45 Days After Deposit |

| L/D: | 48 | Screw & Barrel Material: | W6Mo5Cr4V2 |

| Motor: | 90kw | Capacity: | 300-500kg/h |

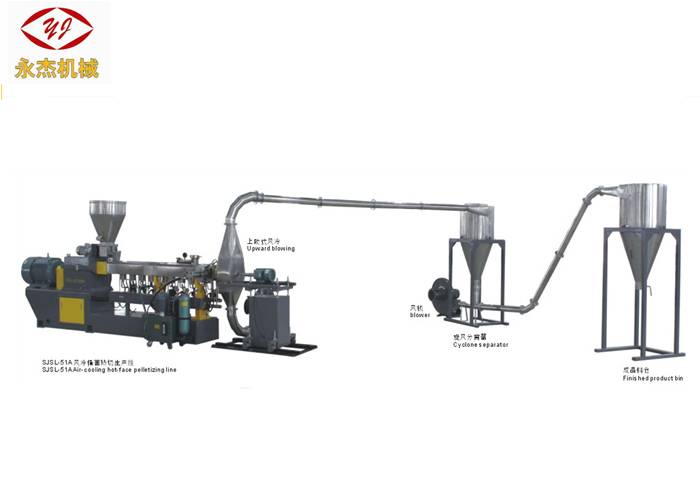

Twin Screw Exturder Black Masterbatch Machine Water Ring Pelletizer

Water Ring Pelletizer Application:

1. PE, Eva etc + Caco3, talk, Tio92, filling modification and carbon black etc.

2. LDPE, HDPE, LLDPE,MDPE, drivepipe, insulation material, crosslinking material, cable coating material, thermal contraction pipe material etc.

3. PPR pipe compounds, PE crosslinking tube material, TPR, TPU thermoplastic elastomer, EVA and hot melt adhesive etc.

4. PE, ABS, PS, EVA masterbatch etc.

5. ABS, EVA flaming retarding masterbatch etc.

6. PE, PP, PS filling and biodegradable masterbatch, etc.

Quick details of sjsl36 water ring pelletizer

Screw diameter:62.4mm

Screw material:W6Mo5Cr4V2

Barrel diameter:63mm

Barrel material:W6Mo5Cr4V2

Motor power:90kw

Motor brand:SIEMENS

L/D:48:1 etc

Output:300-500kg/h

Main parts and technical parameters

| No. | Contents | Unit | Quantity | Marks |

| 1 | 200L high speed mixer | set | 1 | |

| 2 | Twin screw extrusion system | set | 1 | |

| 2.1 | Feeding system | set | 1 | 1.1kw |

| 2.2 | SJ-51 Twin screw extruder | set | 1 | 90kw, 48:1 |

| 2.3 | Vacuum venting system | set | 1 | 2.2kw |

| 2.4 | Water cycling system | set | 1 | 0.55kw |

| 2.5 | Automatic screen changer | set | 1 | 1.5kw |

| 3 | Electric cabinet | set | 1 | |

| 4 | Water-ring auxiliary system | set | 1 | |

| 4.1 | Water-ring die head | set | 1 | |

| 4.2 | Face cutter with guide rail & cover | set | 1 | 1.5KW |

| 4.3 | Centrifugal dehydrator | set | 1 | 4KW |

| 4.4 | Vibrating sieve | set | 1 | 0.4KW |

| 4.5 | Storage bin | set | 1 | |

| 5 | Documents | set | 1 |

Business Clause

Lead time:45 days after deposit

Engineers available for overseas installation, commissioning etc

Payment term:30% deposit via TT, 70% balance before shipment after testing and qualifying machine at seller’s manufacturer, L/C payment are negotiable

| Model type | Series | Barrel Diameter (mm) | Screw Diameter (mm) | Screw L/D | screw speed n(r/min) | Main motor power(Kw) | Screw torque T(N.m) | Torque rating (T/A3) | Typical production capacity (kg/h) |

| SJSL-36 | A/B/C/D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A/B/C/D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A/B/C/D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A/B/C/D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A/B/C/D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A/B/C/D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |

Product detail pictures:

Related Product Guide:

Cooperation

Assume full accountability to satisfy all demands of our consumers; reach ongoing advancements by endorsing the expansion of our purchasers; come to be the final permanent cooperative partner of clients and maximize the interests of clientele for OEM Factory for Plastics Water Ring Pelletizer - 90kw Motor HDPE Granulator Pellet Manufacturing Equipment With Water Cycling System – Yongjie , The product will supply to all over the world, such as: Latvia, Dubai, France, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to for you of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we are going to have a bright prospect and to be distributed all over the world in the years to come.

This supplier offers high quality but low price products, it is really a nice manufacturer and business partner.