OEM Supply Twin Screw Extruder Lab - 21.7mm Screw Lab Twin Screw Extruder With Water Cycling System Copper Heater – Yongjie

OEM Supply Twin Screw Extruder Lab - 21.7mm Screw Lab Twin Screw Extruder With Water Cycling System Copper Heater – Yongjie Detail:

| Screw Design: | Twin Screw Extruder | Heater: | Cast Copper |

|---|---|---|---|

| Heater Power: | 16kw | Barrel Diameter: | 22mm |

| Screw Diameter: | 21.7kw | Capacity: | 2-15kg/h |

| L/D: | 40:1 | Warranty: | One Year |

SJSL20 Copper Heater 21.7mm Screw Lab Twin Screw Extruder Plastic Granulating Machine

Quick details

Power:5.5kw

Screw material:W6Mo5Cr4V2

Barrel material: 45#forged steel with the abrasion-resistant alloy 101 (Ni-Fe-Cr-W) inside that smooth

and abrasion resistant. The hardness is HRC60-64.

L/D:40:1

Output:20-70kg/h according to different material, formula and technology of process etc.

Revolutions: 0-600rpm;

Reduction ratio: i = 2.5:1

Core axle: High quality alloy steel 40CrNiMo that with high tenacity and durability. It had been treated by the hardening and tempering process.

Screw diameter:21.7mm

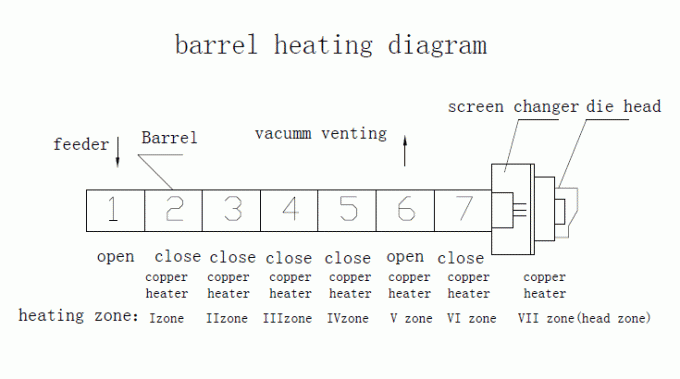

Barrel diameter:22mm, The first section works for main feeding, the fifth section is set up for venting naturally, and the ninth section is set up for vacuum venting and others are blocked.

Scope of supply

| No. | Contents | Unit | Quantity | Marks |

| 1 | High speed mixer | set | 1 | 5L |

| 2 | Twin screw extrusion system | set | 1 | |

| 2.1 | Feeding system | set | 1 | 0.25kw |

| 2.2 | SJ-20 Twin screw extruder | set | 1 | 5.5kw, 40:1 |

| 2.3 | Vacuum venting system | set | 1 | 0.75kw |

| 2.4 | Water cycling system | set | 1 | 0.55kw |

| 2.5 | Manual screen changer | set | 1 | |

| 3 | Electric cabinet | set | 1 | |

| 4 | Water stand auxiliary system | set | 1 | |

| 4.1 | Die head | set | 1 | |

| 4.2 | Water trough | set | 1 | 1 M |

| 4.3 | Dryer | set | 1 | 0.26KW |

| 4.4 | Pelletizer | set | 1 | 0.75KW |

| 5 | Documents | set | 1 |

Pre-sales service

♦1. Inquiry and consulting support.

♦2. Selecting economical and suitable extruder and related machines for customers.

♦3. Providing technical details of machine.

♦4. Providing means of trial performance for customer.

♦5. Factory tour & assistance of invitation letter when needed.

Sales service

♦1. Recommending engineering conditions required for installation.

♦2. Communicating on time the manufacturing status of machines.

After-sales service

♦1. Engineers available to service machinery overseas in installation, commissioning and training.

♦2. Filing in detail customer’s order information.

♦3. Providing long-term maintenance service and spare parts.

♦4. Giving technical support to customer for developing new product.

♦5. Providing free maintenance for a year.

Photo of SJSL20 lab mini extruder

Main technical data of various model of twin screw extruder pelletizing machine

| Model type | Series | Barrel Diameter (mm) | Screw Diameter (mm) | Screw L/D | screw speed n(r/min) | Main motor power(Kw) | Screw torque T(N.m) | Torque rating (T/A3) | Typical production capacity (kg/h) |

| SJSL-20 | A/B | 21.7 | 22 | 32-44 | 400/600 | 4/5.5 | 30 | 4.8 | 2-15 |

| SJSL-36 | A/B/C/D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A/B/C/D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A/B/C/D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A/B/C/D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A/B/C/D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A/B/C/D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |

Company Brief

Nanjing Yongjie Qixin Machinery Equipment Co.,Ltd Founded in 2001, covers an area of 20,000 square meters on our own land, with monthly output of machine 20sets. Our factory is certificated to CE, ISO9001:2008.The company concentrates on research, development and production of “high level, accurate, highly sophisticated series product parallel co-rotating “cordwood” twin screw extruder, single screw extruder, two stage extruders and automatic plastic pelletizing machines. We have provided customers first-class products with “strong torque, high production, energy conservation and environmental protection products. The special designed screw structure has realized successfully for “one step shaping” on many kinds of products, and is widely used in aluminum composite plate, XPS foaming plate, WP plate, PP, PE sheet industry, etc.

Product detail pictures:

Related Product Guide:

Cooperation

Innovation, quality and reliability are the core values of our company. These principles today more than ever form the basis of our success as an internationally active mid-size company for OEM Supply Twin Screw Extruder Lab - 21.7mm Screw Lab Twin Screw Extruder With Water Cycling System Copper Heater – Yongjie , The product will supply to all over the world, such as: Ottawa, Iraq, Thailand, We can meet the various needs of customers at home and abroad. We welcome new and old customers to come to consult & negotiate with us. Your satisfaction is our motivation! Allow us to work together to write a brilliant new chapter!

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.