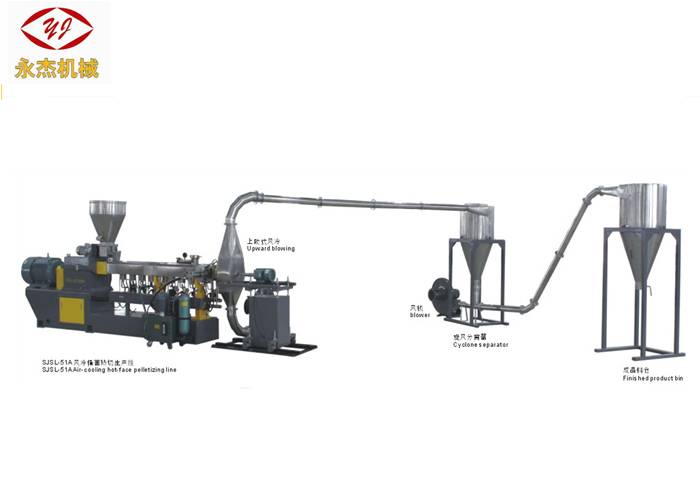

OEM/ODM China Wpc Pelletizing Machine – Hot Cutting Double Screw WPC Extruder Machine 400-500kg/H Capacity Long Span Life – Yongjie

OEM/ODM China Wpc Pelletizing Machine – Hot Cutting Double Screw WPC Extruder Machine 400-500kg/H Capacity Long Span Life – Yongjie Detail:

| Plastic Type: | PP/PE/PVC/POM Etc+wood Fiber | Warranty: | One Year |

|---|---|---|---|

| Color Of Machine: | Any Color Available | Barrel Diameter: | 71.8mm |

| Screw & Barrel Material: | W6Mo5Cr4V2 | Motor: | 160kw |

| Cutting Type: | Air Cooling Hot Cutting | Capacity: | 400-500kg/h |

WPC Filler Masterbatch Hot Cutting Double Screw WPC Extruder Machine

Air Cooling Die Face PVC Pelletizing Machine Application

Enforcing modification: PE, EVA etc+Caco3, Talc, Tio2, PVC, PP, Carbon black

Degradable master batch: PE, PS etc. + starch, additive etc

Anti-flake master batch: PE, EVA etc+Sb2o3, Mg(OH)2, AI2(OH)3 etc.

Quick details of machine

1. Gearbox

Transmission gear: Parallel tri-axial structure is combination of reduction and matrix. The gear is made of high quality alloy. It had been treated by cementation heat process, the precision grade can reach6th. It guarantees the tooth surface is high speed, overloading, low noise and high torque.

Drive bearing: The brand of axletree: NSK.

Lubrication: Gear bearings in the gear box will be of oil immersed. There is hydraulic lubrication in the gear engagement and gear bearings.

Cooling: Lubricated cooling adopts shell and tube cooler and circulated water cooling method.

2. Screw & Barrel

Diameter:¢71mm

L/D:40:1

Direction of rotation: Co-rotating

Screw & elements: 38CrMoAlA, surface nitrogen treated, HV = 950 ~ 1100. Using special CNC grinding machine for screw, after dedicated grinding, its curve fit and surface finish is much better than screw elements treated by conventional processing method

Core axle: High quality alloy steel 40CrNiMo that with high tenacity and durability. It had been treated by the hardening and tempering process.

1). Diameter: ¢71.8mm 2). Structure: The first section works for main feeding, the fifth section is set up for venting naturally, and the ninth section is set up for vacuum venting and others are blocked. 3). Material: 38CrMoAlA, surface nitrogen treated, HV = 950 ~ 1100.

4). Heating: Adopt multiple step format electric heating. The first and the second zone and the machine head zone are cast copper heater and others are cast aluminum heater. The total heating power is 60kw and the max heating capacity every section can reach 500℃.

5). Cooling: Adopt soft water cooling system in the barrel and tap water cooling way outside barrel. The circulation pipes are made of stainless steel and the water inflow regulating valves are stainless valves.

The brand of electromagnetic valve is DANFOSS.

6) Length:290*10=2900mm

| No. | Contents | Unit | Quantity | Marks |

| 1 | Twin screw extrusion system | set | 1 | |

| 1.1 | Feeding system | set | 1 | 1.5kw |

| 1.2 | SJ-75B Twin screw extruder | set | 1 | 160kw, 40:1 |

| 1.3 | Water cycling system | set | 1 | 0.55kw |

| 2 | Electric cabinet | set | 1 | |

| 3 | Air-cooling auxiliary system | set | 1 | |

| 3.1 | Die head | set | 1 | |

| 3.2 | Face cutter | set | 1 | 1.5kw |

| 3.3 | Two-stage conveying system | set | 1 | 4kw/set, 8kw totally |

| 3.4 | Product silo | set | 1 | 4kw |

| 4 | Documents | set | 1 |

Free spare parts:

| No. | Contents | Unit | Quantity | Marks |

| 1 | Screw elements | set | ~500mm | |

| 2 | Output and input shaft oil seals | piece | 3 | |

| 3 | Venting room seal ring | piece | 1 | |

| 4 | Asbestos gloves | pairs | 2 | |

| 5 | Allen key (inner) | set | 1 | 5 pieces |

| 6 | Allen key (outer) | set | 1 | 3 pieces |

| 7 | Flat, Cross Screw driver | piece | 1 each | 2 pieces |

| 8 | Copper bar ∮32*200 | piece | 1 | |

| 9 | Screw hoisting ring | piece | 2 | |

| 10 | Blade | piece | 30 |

Main models of our twin screw extruder

| Model type | Series | Barrel Diameter (mm) | Screw Diameter (mm) | Screw L/D | screw speed n(r/min) | Main motor power(Kw) | Screw torque T(N.m) | Torque rating (T/A3) | Typical production capacity (kg/h) |

| SJSL-36 | A/B/C/D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A/B/C/D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A/B/C/D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A/B/C/D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A/B/C/D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A/B/C/D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |

FAQ

1. Are you a factory or trading company?

Both.

2. Where is your factory located? How can I visit there?

Our factory is located in industrial centralized area of Moling town, Jiangning, Nanjing, China.

(1) You can fly to Nanjing Airport directly. We will pick you up on Nanjing Lukou International airport;

(2) You can fly to Shanghai Pudong International Airport then come to Nanjing by High-speed railway, then we will pick you up in the railway station.

3. What’s your advantages?

(1) Excellent quality control

(2) First-class service

(3) Professional Tech. and R&D team

(4) Quick manufacturing time

(5) Quite competitive price

4. How long is the delivery time?

Under normal conditions, products are delivered within 35 days.

5. How can I know the stauts of my order?

We will send you photos and videos of your order at different satge in time and keep you informed of the latest information.

6. How long is the warranty?

We can offer one-year warranty for the whole machine.

Product detail pictures:

Related Product Guide:

Cooperation

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" plus the theory of "quality the basic, have faith in the main and management the advanced" for OEM/ODM China Wpc Pelletizing Machine – Hot Cutting Double Screw WPC Extruder Machine 400-500kg/H Capacity Long Span Life – Yongjie , The product will supply to all over the world, such as: Belize, Luxembourg, Romania, Look forward to the future, we'll focus more on the brand building and promotion . And in the process of our brand global strategic layout we welcome more and more partners join us, work together with us based on mutual benefit. Let's develop market by fully utilizing our in depth advantages and strive for building.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!