Professional China China Water Ring Pelletizer Company - Twin Screw Extruder Water Ring Pelletizer For Caco3 Masterbatch Manufacturing – Yongjie

Professional China China Water Ring Pelletizer Company - Twin Screw Extruder Water Ring Pelletizer For Caco3 Masterbatch Manufacturing – Yongjie Detail:

| Dehydrator: | 2.2kw | Product Silo: | 3kw |

|---|---|---|---|

| Warranty: | One Year | Lead Time: | 45 Days After Deposit |

| Barrel Diameter: | 36mm | Screw & Barrel Material: | W6Mo5Cr4V2 |

| Motor: | 18.5kw | Capacity: | 50-80kg/h |

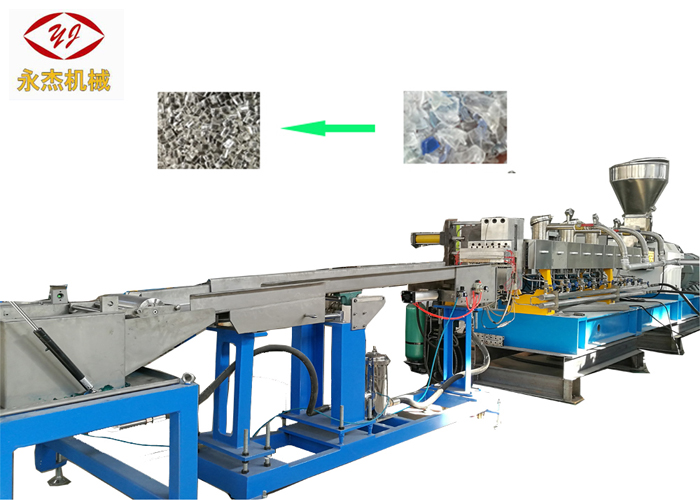

Caco3 Masterbatch Manufactureing Machine Twin Screw Extruder Water Ring Pelletizer

Water Ring Pelletizer Application:

1. PE, Eva etc + Caco3, talk, Tio92, filling modification and carbon black etc.

2. LDPE, HDPE, LLDPE,MDPE, drivepipe, insulation material, crosslinking material, cable coating material, thermal contraction pipe material etc.

3. PPR pipe compounds, PE crosslinking tube material, TPR, TPU thermoplastic elastomer, EVA and hot melt adhesive etc.

4. PE, ABS, PS, EVA masterbatch etc.

5. ABS, EVA flaming retarding masterbatch etc.

6. PE, PP, PS filling and biodegradable masterbatch, etc.

Quick details of sjsl36 water ring pelletizer

Screw diameter:35.6mm

Screw material:W6Mo5Cr4V2

Barrel diameter:36mm

Barrel material:W6Mo5Cr4V2

Motor power:18.5kw

Motor brand:SIEMENS

Inverter:ABB

Centrifugla dehydrator:2.2kw

Product silo:3kw

L/D:44:1

Output:50-80kg/h

Scope of supply of sjsl36 water ring pelletizer

| No. | Contents | Unit | Quantity | Marks |

| 1 | Twin screw extrusion system | set | 1 | |

| 1.1 | High speed mixer | set | 1 | 50L |

| 1.2 | Main feeding system | set | 1 | 0.75KW |

| 1.3 | SJ36 twin screw extruder | set | 1 | 18.5KW, 44:1 |

| 1.4 | Vacuum venting system | set | 1 | 0.75KW |

| 1.5 | Water recycling system | set | 1 | 0.55KW |

| 1.6 | Hydraulic screen changer | set | 1 | 0.75KW |

| 2 | Electric cabinet | set | 1 | |

| 3 | Water-ring assembly system | set | 1 | |

| 3.1 | Die head | set | 1 | |

| 3.2 | Face cutter | set | 1 | 1.5KW |

| 3.3 | Water-ring cutting cover | set | 1 | |

| 3.4 | Centrifugal dehydrator | set | 1 | 2.2KW, 3KW |

| 3.5 | Production container | set | 1 | 3KW |

| 4 | Documents | set | 1 |

World famous brands of electronic components

1). Temperature control meter is Japanese RKC meter, intelligent type, double channel;

2). The inverter of extruder is ABB;

3). The low-voltage apparatus and the button adopt SCHNEIDER product;

4). AC contactor adopt SIEMENS product;

5). The main motor is SISMENS BEIDE;

6). The air switch adopts CHINT products. The solid-state relays are from American joint venture brand;

7). The electromagnetic valve: adopt Denmark DANFOSS product.

Main Technical Details of Plastic Pelletizing Machine Models

| Model type | Series | Barrel Diameter (mm) | Screw Diameter (mm) | Screw L/D | screw speed n(r/min) | Main motor power(Kw) | Screw torque T(N.m) | Torque rating (T/A3) | Typical production capacity (kg/h) |

| SJSL-36 | A/B/C/D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A/B/C/D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A/B/C/D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A/B/C/D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A/B/C/D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A/B/C/D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |

Product detail pictures:

Related Product Guide:

Cooperation

Our organization promises all customers with the first-class products and solutions and the most satisfying post-sale service. We warmly welcome our regular and new clients to join us for Professional China China Water Ring Pelletizer Company - Twin Screw Extruder Water Ring Pelletizer For Caco3 Masterbatch Manufacturing – Yongjie , The product will supply to all over the world, such as: Philippines, Vietnam, Rio de Janeiro, Since the establishment of our company, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.