Heavy Duty Plastic Recycling Pellet Machine W6Mo5Cr4V2 Screw & Barrel Material

| Screw Design: | Twin Screw Extruder | Application: | PP PE With Caco3, Talc Etc Filler Masterbatch |

|---|---|---|---|

| Warranty: | One Year | Lead Time: | 45 Days After Deposit |

| Barrel Diameter: | 50.5mm | Screw & Barrel Material: | W6Mo5Cr4V2 |

| Motor: | 45kw | Capacity: | 100-250kg/h |

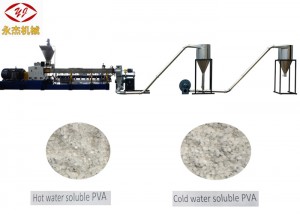

Black Masterbatch Extruder Water Ring Pelletizer Twin Screw Extruder

Water Ring Pelletizer Application:

1. PE, Eva etc + Caco3, talk, Tio92, filling modification and carbon black etc.

2. LDPE, HDPE, LLDPE,MDPE, drivepipe, insulation material, crosslinking material, cable coating material, thermal contraction pipe material etc.

3. PPR pipe compounds, PE crosslinking tube material, TPR, TPU thermoplastic elastomer, EVA and hot melt adhesive etc.

4. PE, ABS, PS, EVA masterbatch etc.

5. ABS, EVA flaming retarding masterbatch etc.

6. PE, PP, PS filling and biodegradable masterbatch, etc.

Quick details of sjsl36 water ring pelletizer

Screw diameter:50.5mm

Screw material:W6Mo5Cr4V2

Barrel diameter:51mm

Barrel material:W6Mo5Cr4V2

Motor power:45kw

Motor brand:SIEMENS

L/D:44:1 or 48:1 etc

Output:100-250kg/h

Work condition (provided by customer)

| Warehouse/Workshop | Dimension (M*M*M): 15 (Length)×3 (width) ×2.5 (Height)Crane: Machine positioning |

| Temperature | ≤40℃ |

| Power supply & Installation power | 3-phase, 380V, 50Hz |

| Wire/cables | Wires/cables from power supply to control cabinet of this production line;All electrical cables from control cabinet to each machine. |

| Cooling Water hose/pipe | Water supply to machines and pools. Creating a pool (4-6m3) outside the workshop, using water pump to make recycling water. |

| Weight | Extruder: ~2.5T, sub-machine: ~1T |

Main parts and technical parameters

| No. | Contents | Unit | Quantity | Marks |

| 1 | 100L high speed mixer | set | 1 | |

| 2 | Twin screw extrusion system | set | 1 | |

| 2.1 | Feeding system | set | 1 | 0.75kw |

| 2.2 | SJ-51 Twin screw extruder | set | 1 | 45kw, 44:1 |

| 2.3 | Vacuum venting system | set | 1 | 1.5kw |

| 2.4 | Water cycling system | set | 1 | 0.55kw |

| 2.5 | Automatic screen changer | set | 1 | 1.5kw |

| 3 | Electric cabinet | set | 1 | |

| 4 | Water-ring auxiliary system | set | 1 | |

| 4.1 | Water-ring die head | set | 1 | |

| 4.2 | Face cutter with guide rail & cover | set | 1 | 1.5KW |

| 4.3 | Centrifugal dehydrator | set | 1 | 4KW |

| 4.4 | Vibrating sieve | set | 1 | 0.4KW |

| 4.5 | Storage bin | set | 1 | |

| 5 | Documents | set | 1 |

Main Technical Details of Various Water Ring Pelletizer Models

| Model type | Series | Barrel Diameter (mm) | Screw Diameter (mm) | Screw L/D | screw speed n(r/min) | Main motor power(Kw) | Screw torque T(N.m) | Torque rating (T/A3) | Typical production capacity (kg/h) |

| SJSL-36 | A/B/C/D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A/B/C/D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A/B/C/D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A/B/C/D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A/B/C/D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A/B/C/D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |