Heavy Duty Master Batch Manufacturing Machine W6Mo5Cr4V2 Screw & Barrel Material

| Screw Design: | Twin Screw Extruder | Application: | PP PE +80% Calcium Carbonate |

|---|---|---|---|

| Warranty: | One Year | Screw Material: | W6Mo5Cr4V2 |

| L/D: | 48:1 | Screw & Barrel Material: | W6Mo5Cr4V2 |

| Motor: | 110kw | Capacity: | 500-800kg/h |

500-800kg/h Twin Screw Extruder Water Ring Pelletizer Filer Masterbatch Manufacturing Machine

Water Ring Pelletizer Application:

1. PE, Eva etc + Caco3, talk, Tio92, filling modification and carbon black etc.

2. LDPE, HDPE, LLDPE,MDPE, drivepipe, insulation material, crosslinking material, cable coating material, thermal contraction pipe material etc.

3. PPR pipe compounds, PE crosslinking tube material, TPR, TPU thermoplastic elastomer, EVA and hot melt adhesive etc.

4. PE, ABS, PS, EVA masterbatch etc.

5. ABS, EVA flaming retarding masterbatch etc.

6. PE, PP, PS filling and biodegradable masterbatch, etc.

Quick details of sjsl36 water ring pelletizer

Screw diameter:71mm

Screw material:W6Mo5Cr4V2

Barrel diameter:71.8mm

Barrel material:W6Mo5Cr4V2

Motor power:110kw

Motor brand:SIEMENS

L/D:48:1 52:1etc

Output:500-800kg/h

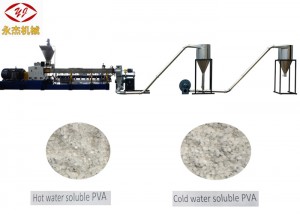

Photo of SJSL75A water ring pelletizier filler masterbatch machine

Pre-sales service

♦1. Inquiry and consulting support.

♦2. Selecting economical and suitable extruder and related machines for customers.

♦3. Providing technical details of machine.

♦4. Providing means of trial performance for customer.

♦5. Factory tour & assistance of invitation letter when needed.

Sales service

♦1. Recommending engineering conditions required for installation.

♦2. Communicating on time the manufacturing status of machines.

After-sales service

♦1. Engineers available to service machinery overseas in installation, commissioning and training.

♦2. Filing in detail customer’s order information.

♦3. Providing long-term maintenance service and spare parts.

♦4. Giving technical support to customer for developing new product.

♦5. Providing free maintenance for a year.

Main Technical Details of Various Water Ring Pelletizer Models

| Model type | Series | Barrel Diameter (mm) | Screw Diameter (mm) | Screw L/D | screw speed n(r/min) | Main motor power(Kw) | Screw torque T(N.m) | Torque rating (T/A3) | Typical production capacity (kg/h) |

| SJSL20 | A/B | 22 | 21.7 | 32-44 | 500/600 | 4/5.5kw | 30/30 | ||

| SJSL-36 | A/B/C/D | 36 | 35.6 | 32-48 | 400/600 | 11/15/18.5/22 | 125-225 | 4.6-8.3 | 30-120 |

| SJSL-51 | A/B/C/D | 51 | 50.5 | 32-52 | 500/600 | 45/55/75/90 | 405-680 | 5.1-8.5 | 120-400 |

| SJSL-65 | A/B/C/D | 63 | 62.4 | 32-64 | 500/600 | 75/90/110/132 | 680-1200 | 4.8-8.5 | 180-750 |

| SJSL-75 | A/B/C/D | 72 | 71 | 32-64 | 500/600 | 110/132/160/250 | 995-1890 | 4.6-8.7 | 300-1200 |

| SJSL-95 | A/B/C/D | 94 | 93 | 32-64 | 500/600 | 250/315/450/550 | 2260-4510 | 4.7-8.7 | 700-2500 |

| SJSL-135 | A/B/C/D | 135 | 133 | 32-48 | 400/500 | 550/750/900/1200 | 6200-10800 | 4.4-7.7 | 1550-6500 |